avance embroidery machine thread breaks

Is the thread breaking on just one needle or all needles. For more tips and tricks on embroidery visit our blog at httpswwwem.

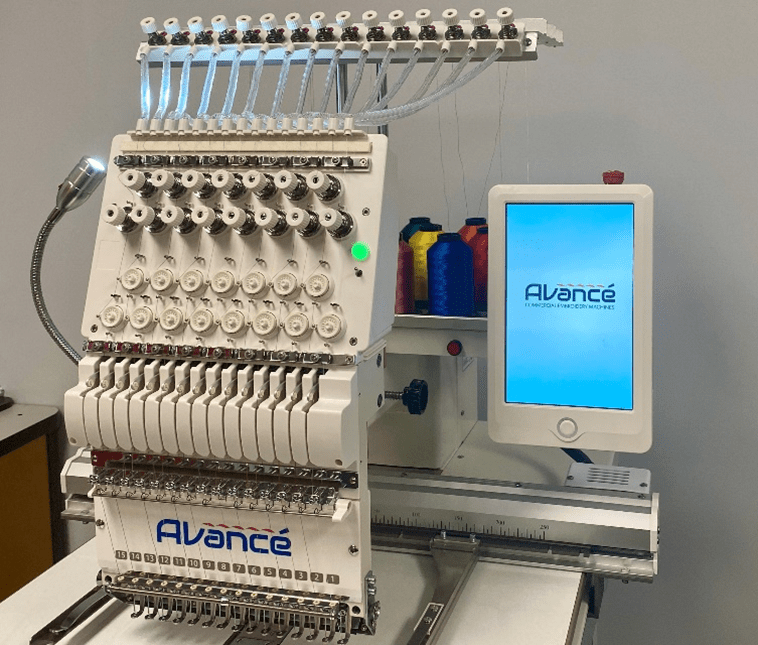

Avance 1501c Multi Head Embroidery Machine Options Avance Commercial Embroidery Machines

Press or press and hold STOP to move sewing position to just before the break.

. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. Full color touch screen control panel - makes it so simple to use. Firmly set the fabric in the embroidery frame so that it is taut.

There may be a chance the sensor was installed backwards or upside down. If youre still having trouble with thread breakage its possible the bobbin case needs to be replaced. The Avancé 1201C is a 12 needle embroidery machine designed to give you that combination of price features and reliability that makes it easy to get into the commercial embroidery business.

28 on board fonts for easy monogramming and lettering projects. While stitching out a job you should have a thread break as soon as the job ends otherwise the job will continue stitching wasting time and material. USB Port - Convenient design load.

Make sure your thread isnt too tight or too loose. Deborah Jones shows you what could be causing thread breaks and how to correct them. Use the Troubleshooter below.

Operating an embroidery machine sewing out a design choosing the right supplies are all inter-related. Trim the thread to 3-4 cm before inserting the bobbin and case into the hook assembly. When a thread continues to break during a project it can be exceptionally annoying so finding and solving the problem early on is essential.

True commercial embroidery thread breaks have many causes including abrasion excessive tension or stress. The thread break sensor on Avance machines is automatically activated when a thread breaks. Avance embroidery machine review.

The black pieces on the thread break sensor should pass through the direct center of the metal wheel. What causes thread breaks redline embroidery machines. 101 Full color high resolution touch screen interface.

This will prevent the thread from twisting as it comes off the spool. Long tails can cause the bobbin thread to tangle when the machine begins to stitch. The first step is checking the tightness of the bobbin thread.

So getting trained one problem at a time is a recipe for frustration not success. Then in future projects the thread can easily break. To help prevent thread breaks caused by tension perform an I test or stitch a one-inch satin column on each of your machines needles.

Thread breakage is often caused by tension. The reason they do that is simple. This may happen after the needle.

The thread break sensor on Avance machines is automatically activated when a thread breaks. Using a flat head screw that was provided to you labeled Minus Driver Small tighten the adjusting screw one to two minutes 1 to the right. Press TCUT to cut thread still attached to garment2.

Avance Embroidery Machine Thread Breaks. The first step in identifying the problem is as simple as. If a thread breaks during the restitching process the Avante.

This is a good method to determine what the issue is. Repair thread break by re-threading upper thread or replacing bobbin. Thread breaking in embroidery machine is the worst thing and to avoid you must follow these steps Reduce the number of stitches and stitch lenght first from your embroidery design.

Also if the needle is too old and worn out it can also shred the thread. Thread frays usually have more to do with timing burrs and nicks in the thread path. You should also check the condition of your needle.

Problem may re-occur without proper troubleshooting. Thread breaks can be caused by tension issues machine timing thread path interference thread caught under spool old or Rayon thread or poor digitizing. Rather than having your thread come off the spool vertically set up the spool horizontally.

If its slightly off that could cause false thread breaks. To help prevent further. Avance embroidery machine thread breaks Tuesday February 22 2022 Edit.

You can schedule training here. There are a number of reasons thread can break in an embroidery machine ranging from the age of the thread to the maintenance of the machine. Unbeatable Prices And Selection.

Thread passing through the smaller eye within a sewing needle can easily get snagged and break. Embroidery Textile Printers Printers-Screen Printing. See reviews photos directions phone numbers and more for the best Embroidery in Piscataway NJ.

You ought to lower the machine speed as required. Remove any knots or tangles. Needles can easily get bent if they run into a hard or stiff surface.

To illustrate this point think about how toilet paper naturally comes off the roll when laid vertically how it usually is. See reviews photos directions phone numbers and more for Say It With Thread locations in Piscataway NJ. Browse Our Huge Selection Of Top Brands Online.

Check for any lint in the machine that might cause. Ad We Have All Of Your Embroidery Needs Covered. A lint build up around the tension discs needle plate or bobbin cases could cause breakage.

We Pass Savings On To You. To help prevent further thread breaks. The thread break sensor on Avance machines is automatically activated when a thread breaks.

Your needle may be dull and need to be changed so try a new needle size. Be sure to use the correct bobbin. Turn to Madeira USA for all your embroidery thread and embroidery supply needs.

Some Embroidery designs increase the stress on thread. Is the thread breaking on just one needle or all. For example the Brother PE800 requires 90wt embroidery thread.

The paper comes off as it was put on without issue now. If the sensor is installed properly check to make sure it is aligned to the center of the metal wheel. These areas ought to be cleaned regularly with air or maybe a brush.

HUGE design memory on board - 800 designs or 100 million stitches. Answer yes or no questions and. Most of the time bobbin tension should be set at about 25 grams and the top thread should be at 110 to 150 grams for polyester 100 to 140 grams.

Ideal tension settings will display one-third bobbin thread down the center and one-third top thread down both sides of the column on the back of the design. Press START to continue sewing. The black pieces on the thread break sensor should pass through the direct center of the metal wheel.

Tech Talk Stop Breaking Needles Avance Embroidery Machine Youtube

Single Head Multi Needle Embroidery Machine Janome

Commercial Embroidery Machine By Avance Best Single Head Brand Usa

Avance Training Resolving Common Errors Common Start Up Errors Youtube

Commercial Embroidery Thread Breaks True Or False

Coldesi Inc Announces New 12 Needle Embroidery Machine

Avance Single Head Embroidery Support

Commercial Embroidery Machine By Avance Best Single Head Brand Usa

Coldesi Inc Announces The Release Of All New Avance Commercial Embroidery Machine News

Troubleshooting Embroidery Thread Breaks Youtube

Avance 1504 Multihead Commercial Embroidery Machine Demonstration

Avance Training Repairing A Thread Break Bobbin Run Out Youtube

8 Tips To Fix Birdnesting In Embroidery

Why Thread Breaks Happen And How To Avoid Them Ricoma Blog

Commercial Embroidery Thread Breaks True Or False

Commercial Embroidery Machine By Avance Best Single Head Brand Usa

Monogramming Machine Google Search Computerized Embroidery Machine Swf Embroidery Machine Machine Embroidery

Commercial Embroidery Machine By Avance Best Single Head Brand Usa

Setting And Troubleshooting Tensions On The Avance 1501c Youtube